CNC water cooling and the PiPod

By Nicola King. Posted

The PiPod is a throwback to a simpler time, before streaming, before automatic shuffle and having Beethoven’s 9th interrupted by ads became the new norm. A time when you’d save up your money, go into town, buy a whole album on compact disc or vinyl, and study every aspect of the cover artwork on the long bus ride back before you got back to listen to it. The maker of this device is searching for a time when we listened to music properly, but also had the ability to carry thousands of songs with us on a mobile device. And so he created the PiPod: a portable music device that not only plays tunes, but also displays the artwork that album designers used to take such a lot of effort to get right.

Advertisement

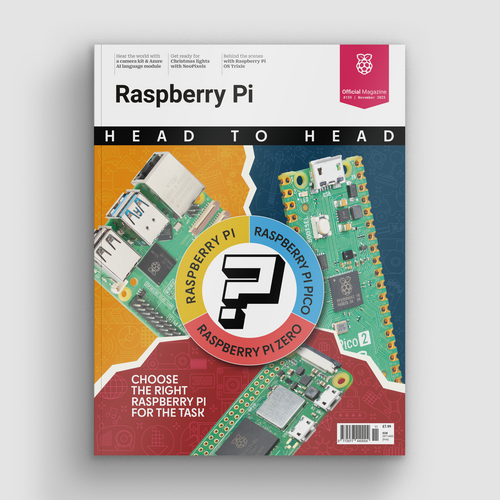

Head to head: Raspberry Pi + Raspberry Pi Zero + Raspberry Pi Pico.

The PiPod uses a USB DAC, components that enable the battery to work (including a battery charge module, battery protection circuit, and a battery indicator module), a Waveshare 4-inch DPI Square Capacitive Screen 720 × 720, and a Raspberry Pi Zero 2 W. Oh, and a 3D printer and about 500g of filament.

The 3D-printed case is shaped to fit around the wearer’s arm, like the phones worn by all those people we see out running. What you see here is not the first iteration; the maker has documented a raft of mistakes, iterations, and happy little accidents to get to the finished version.

CNC water cooling

If your Raspberry Pi 5 is running hot and you want to bring the temperature down a bit, you could try closing a couple of browser tabs. Or open the window. Or maybe buy the official Active Cooler from Raspberry Pi, which clips on and comprises a blower and an aluminium heatsink. In the unlikely event that this isn’t enough, maybe you could take a leaf out of Michael Clements’s book and mill a custom aluminium block, with a milled acrylic reservoir to hold bright green cooling fluid, pumped through a radiator and cooled by a fan running on a separate 12V power supply. As Michael says, this approach is “obviously a totally over-the-top project – but that’s what made it fun”.

Michael milled the aluminium out of a pice of 10mm stock on a Carvera Air home CNC machine; this block makes direct contact with the bits of the Raspberry Pi that produce heat: the CPU, the RAM, the USB and Ethernet controllers, and the power circuitry. On top of this there’s the water block, which also houses the pump. The device is mounted on a 3D-printed stand, with the Raspberry Pi 5 attached to the aluminium block via four M2.5 screws, the holes for which Michael tapped himself.

The sheer ridiculousness of this build (that’s Michael’s own word) is what caught our eye; then when we learned what has gone into it, we were blown away by the variety of different skills he had to use. You’d never know it, but this is the first time he’s had to bend hard-line pipes. It’s incredibly clean, and it works too – so hats off!

Subscribe to Raspberry Pi Official Magazine

Save up to 37% off the cover price and get a FREE Raspberry Pi Pico 2 W with a subscription to Raspberry Pi Official Magazine.

More articles

Teka-Sketch

This all-new e-ink-based Etch-a-Sketch can play Pong, and it also has an undo button

Read more →

Raspberry Pi vs Raspberry Pi Zero 2 vs Raspberry Pi Pico in Raspberry Pi Official Magazine 159

Without an operating system, any computer – including your Raspberry Pi – is just a dumb lump of sand. Put Raspberry Pi OS on it however, and you’ve got yourself a working system that can handle games, web browsers, emails, programming and everything else we bang on about here all day every day. The latest […]

Read more →

Win one of ten M.2 HAT+ Compact

The ability to connect NVME SSD drives to Raspberry Pi 5 is very cool, although it does slightly limit the cases you can use. With the M.2 HAT+ Compact, you can even fit an SSD-powered Raspberry Pi into the official case – and we have ten to give away below. Win one of ten M.2 […]

Read more →

Sign up to the newsletter

Get every issue delivered directly to your inbox and keep up to date with the latest news, offers, events, and more.